Palmer Manufacturing and Tank Inc. has been building tanks for more than 45 years and was incorporated in 1971. Palmer Mfg. is well-known for its strong commitment to excellence within the tank industry as well as its high quality steel and fiberglass products. Our steel tanks meet the strictness of codes set forth by Underwriters Laboratories, American Petroleum Institute and the Steel Tank Institute. Our fiberglass tanks are manufactured using various types of resins that are designated for the type of application needed; along with different types of orientations, diameter, finishes and resistance to corrosion that will aid in the manufacturing of the proper tank to fit each one's needs. Our tanks are built to meet any need you or your company may have.

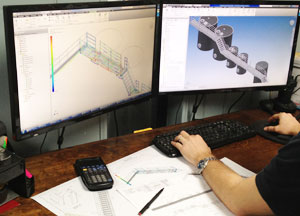

Computer Aided Design And Manufacture

Computer Aided Design And Manufacture is one of the many benefits that the computer age has brought us.

Computer Aided Design And Manufacture is one of the many benefits that the computer age has brought us.

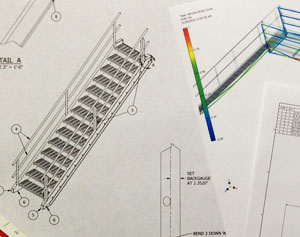

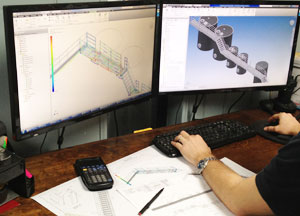

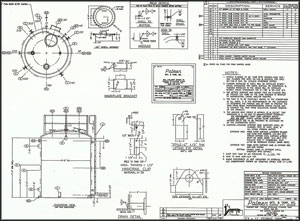

Palmer Manufacturing now offers you this new, exciting technology as applied to tank Engineering, through our state of art CADAM (Computer Aided Design And Manufacture) system.

This system gives our engineers unlimited options and flexibility in designing your fiberglass tank, providing them with a very sophisticated tool to consider in depth all the aspects of tank engineering and manufacture.

Palmer's CADAM system has been closely designed around the sound and long established scientific concepts, both dynamic and static aspects, of fluid and materials mechanics and structural design. Our system also allows for the incorporation of our customers particular data, allowing our engineers to tailor each and every tank we build to the specific needs of every customer.

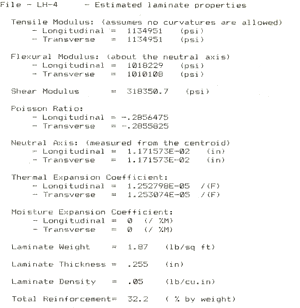

With the use of the CADAM system, our engineers can examine in minute detail critical characteristics of each tank such as axial loading, hoop loading, biaxial loading and torsional loading. Flexural modulus, tensile modulus and shear modulus are also some of the other parameters that can be effectively processed within this program.

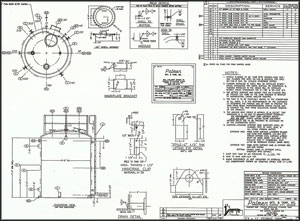

The system was installed with the purpose of better serving our clientele. All print outs plus engineering drawings are available to each customer upon confirmation of the order.

Computer Aided Design And Manufacture is one of the many benefits that the computer age has brought us.

Computer Aided Design And Manufacture is one of the many benefits that the computer age has brought us.